Operation of plants and pipelines

We take responsibility: your hydrogen plants and pipelines are in the best hands with us.

Hydrogen networks must be permanently maintained. This is a task that OGE's technical operations team fulfills responsibly.

A service contract with OGE in accordance with the DVGW worksheets regulates the maintenance of

- ·High-pressure gas pipelines G 466-1

- Gas pressure regulating and metering systems (GDRM) G 495

- Gas transportation compressor systems G 497

- Pipelines and systems for H2

These core tasks are performed by technical operations:

- Plant responsibility (operational asset management)

- Monitoring the systems on site

- Control interventions (operating) on site

- Maintaining / optimizing the systems

- Readiness for fault clearance / ensuring the availability of the systems

Special maintenance tasks as a service:

High-pressure hydrogen pipelines

Tailor-made solutions for the maintenance of high-pressure gas pipelines in accordance with DVGW worksheet G 466-1:

- Inspection, functional testing and maintenance

- Inspection, driving on and flying over pipeline routes

- Clearance snow work

- Coordination and monitoring of third-party construction work

- Maintenance work on fittings, pigging sluices and condensate collectors

- Monitoring cathodic corrosion protection in accordance with DVGW worksheet GW 10

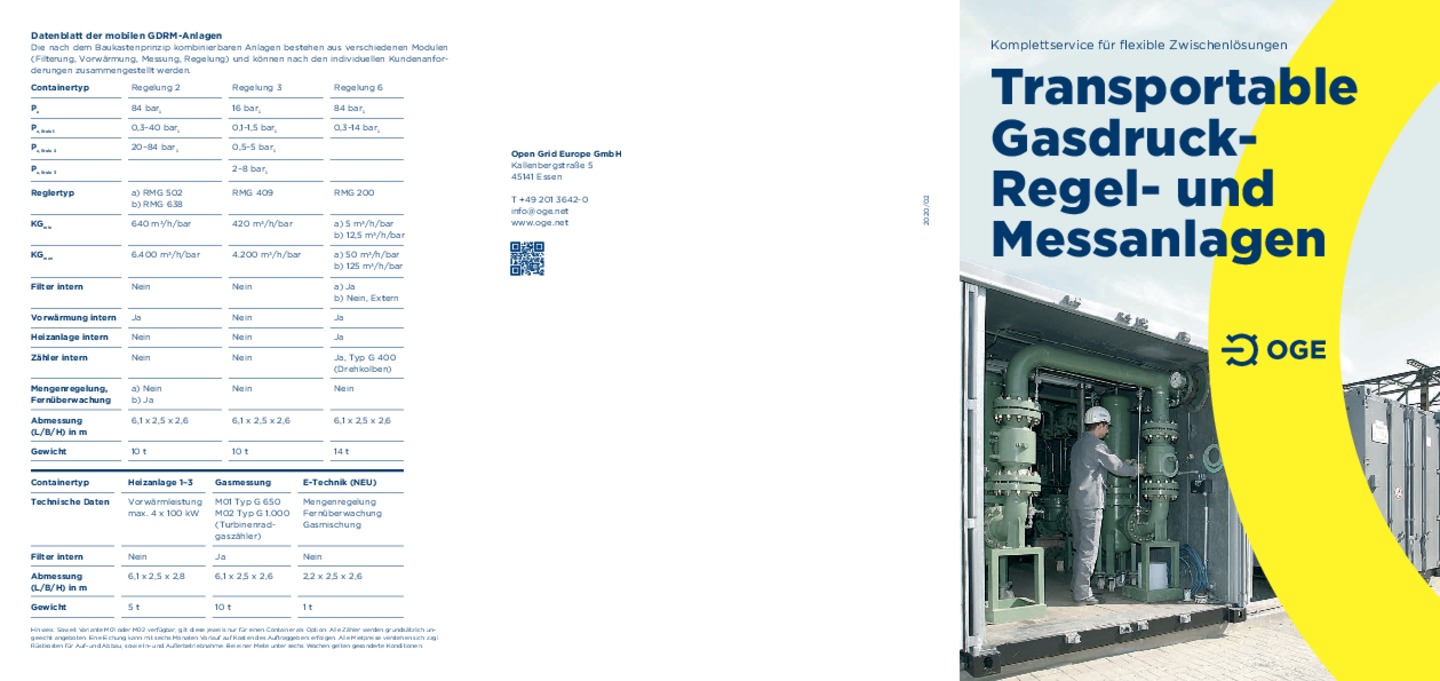

Gas pressure control and measuring systems

Tailor-made solutions for the maintenance of gas pressure regulating and measuring systems in accordance with DVGW Code of Practice G 495:

- Inspection and functional testing (monitoring) of control and safety equipment

- Maintenance of safety devices

- Maintenance of all other components as a result of the functional test (condition-based or needs-based)

- Documentation of all activities

- 24-hour on-call service

Compressor stations

Tailor-made solutions for the maintenance of gas transport compressor stations in accordance with DVGW worksheet G 497:

- Inspection, functional testing and maintenance

- On-site monitoring of the systems

- Operating on site

- Coordination of maintenance, inspection and functional testing of technical equipment (machine units, control and safety equipment etc.)

- Documentation of all activities

- 24-hour on-call service

Are you interested in our products and services?