Andreas, Netzmeister Gas

“Anyone wanting to progress in their career will find all doors are open here.”

Progression – both personal and professional – has been a recurring theme throughout my life. Venturing down new paths instead of just staying put has always paid off for me. And it’s broadened my horizons.

I was born in Leipzig and grew up there in the former East Germany. Then the borders finally opened, and suddenly my parents and I saw the world open up to us. When I was at primary school around the time of reunification in 1990/91, we moved to the West, to Essen.

I settled in, made friends, finished school. And then? A classic apprenticeship seemed to be the right choice. My interest in technology and my father’s career in industry gave me the idea of becoming an industrial mechanic. Ruhrgas AG, the predecessor company of OGE, was considered one of the best places in Essen for this kind of apprenticeship. Just as it is today, back then we apprentices had every opportunity to learn, to try things out, to be trained to a very high standard. But it was clear to us right from the start: We wouldn’t all be able to stay in Essen if we wanted to be taken on permanently.

Off to Lower Franconia

Our field sites are all over the country. This presented a good opportunity for me to stand on my own two feet, to move out of my parents’ house and to gain my independence. I applied for a position as an industrial mechanic at the Rimpar site, north of Würzburg. It’s a beautiful place in hilly Lower Franconia, surrounded by vineyards. Close by is actually the geographical centre of the European Union, so it’s a fitting location for us as an infrastructure provider with a European network!

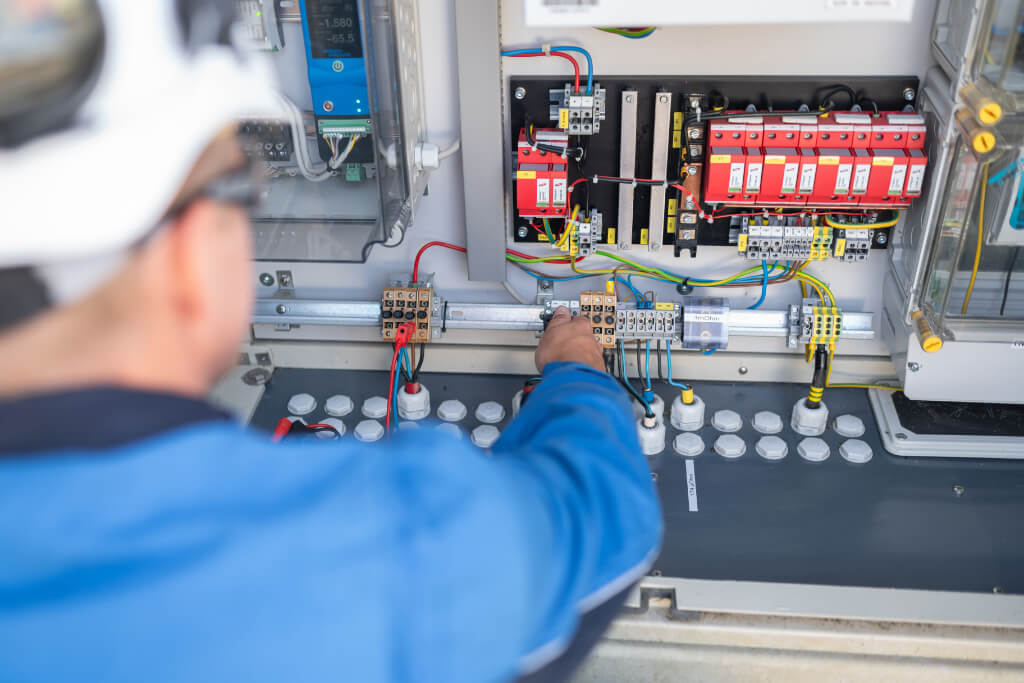

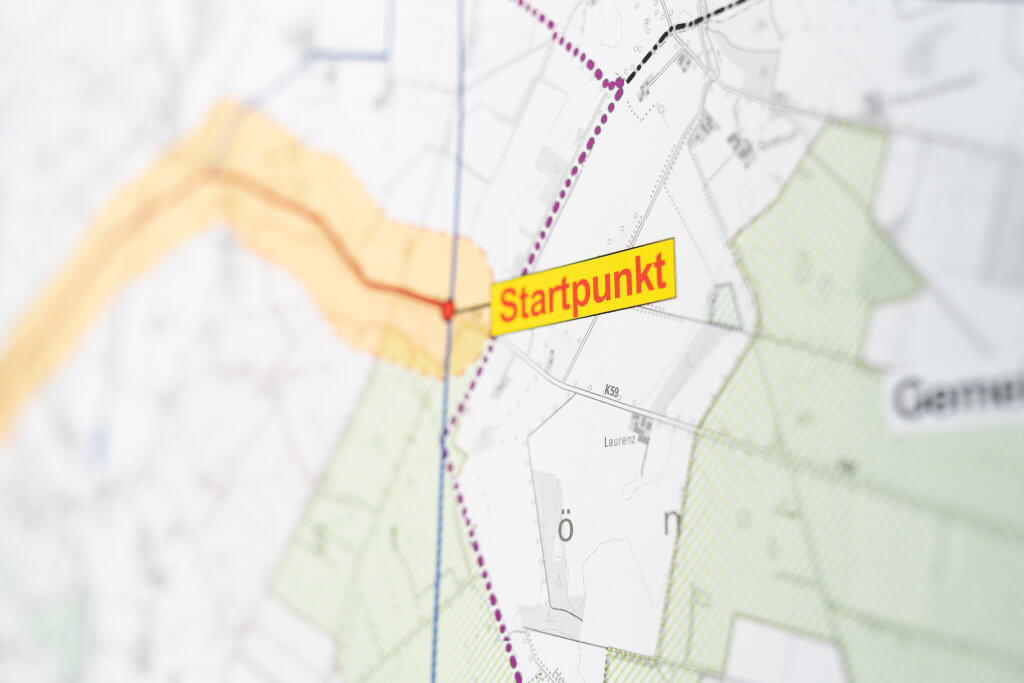

What became my new workplace in Rimpar is one of OGE’s biggest field sites with 35 employees at the compressor station. I initially worked on maintenance here. In pipeline monitoring, we check our pipes for abnormalities and repair any damage. We take care of everything that is “outside the fence”, as we say here, meaning the pipeline network outside the compressor station.

Further training in Cologne

Did I want to work as an industrial mechanic forever? I always enjoyed the tasks, but in 2014 I felt I was ready to take the next step – and become what’s known in German as a “Meister”, a highly skilled foreman. I was always quite ambitious, and I already had a rough idea that I wanted to take on a management role at some point. My supervisors supported me in my plans. The grant for training as an industrial master craftsman in Cologne is a really great bonus of being at OGE. It’s basically a scholarship that enables you to take seven months away from work with full pay to learn the theory in Cologne. One of the advantages is that some of the lecturers there are from OGE, so you have a close connection to your own company and its particular technical circumstances.

After successfully completing my training as an industrial master craftsman, I returned to the Rimpar site, where I initially assumed a subset of the responsibilities of a fully-fledged “Netzmeister Gas”, so it’s like an intermediate stage before you move up fully to the role of gas network foreman.

Coordinating and controlling

These days, my day-to-day work is rarely on the ground along our pipelines, but mostly in the office. Here I rely on the feedback I get from my colleagues, who keep me informed about what is going on with our lines. I always tell them: “You are my eyes, ears and hands!” Whenever work – including any carried out by contractors – could affect our pipelines, I get involved. This might mean dealing with requests for cables to be laid across our gas pipeline route, for example. There is often construction work going on in the vicinity of a pipeline, and we need to monitor, control and manage that. The main consideration here is safety, so everyone involved on site must adhere to the rules of conduct that apply in a safety strip along the gas pipeline.

Ongoing training

Leadership tasks and responsibility for my team are parts of the job I am constantly grappling with. A big help to me here is the further training offered by OGE – for example, the management workshop with regular seminars on various practical topics.

Helping to shape the energy transition

The energy transition and the conversion of our infrastructure for use with hydrogen are aspects that I’ve been very interested in for a long time, especially from a technical perspective. There are a few things that are different from natural gas – and that’s what makes it exciting. The topic of hydrogen will really start to take shape here in southern Germany in the 2030s. The nice thing is that the changes to our pipeline network give us long-term security. The end of natural gas doesn’t mean the end for us – we’ll continue with hydrogen instead. That’s also a good argument when it comes to recruiting new, young colleagues looking for a job with future prospects.

You’ll be a good fit for our team if…

You are open and honest and easy to communicate with. I have to be able to trust my colleagues out on site. If there is a problem, I need to know about it. We can only be effective if we work as a team, so I need people who enjoy real teamwork. Overall, OGE is a great company for an apprenticeship or to advance professionally as a young or experienced specialist.